Plumb_know

TF

- Reaction score

- 1

Hi Everyone,

Plumber by trade but do a lot of bathroom refurbishments, have hired tilers in the past with mixed experiences.

I have not been impressed with the last few tilers and have started doing smaller jobs myself and have enjoyed it. I am not sure if i want to do tilling all the time as like the plumbing work more but would like to learn just so i have a better understanding & to try and provide good preparation for the tilers i do use so they can obtain good results.

I see a lot of people plaster all the walls before tilling a bathroom but i have never done this due to the time needed before you can tile (usually i am redoing the only bathroom in the house so 2weeks without a shower would not go down to well). Is there a better product to use to skim or flatten a wall rather than standard plaster which will allow for tilling say 2 days later?

I would usually dot & dab a wall if possible but some bathrooms i am working with millimetres just to get things to fit in the room.

with regards to walls on stud i usually replace/repair with moisture plasterboard then tank with a mapie type tanking kit, i do this around baths & showers.

Floors i usually lay structural ply then use schluter matting over the top (orange one with grooves)

Does this prep sound reasonable to you and what would you recommend improving?

Also as read on plastering forum never seal with PVA only a tilling primer .

Look forward to you responses & advice.

Thanks

Plumber by trade but do a lot of bathroom refurbishments, have hired tilers in the past with mixed experiences.

I have not been impressed with the last few tilers and have started doing smaller jobs myself and have enjoyed it. I am not sure if i want to do tilling all the time as like the plumbing work more but would like to learn just so i have a better understanding & to try and provide good preparation for the tilers i do use so they can obtain good results.

I see a lot of people plaster all the walls before tilling a bathroom but i have never done this due to the time needed before you can tile (usually i am redoing the only bathroom in the house so 2weeks without a shower would not go down to well). Is there a better product to use to skim or flatten a wall rather than standard plaster which will allow for tilling say 2 days later?

I would usually dot & dab a wall if possible but some bathrooms i am working with millimetres just to get things to fit in the room.

with regards to walls on stud i usually replace/repair with moisture plasterboard then tank with a mapie type tanking kit, i do this around baths & showers.

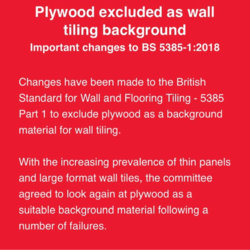

Floors i usually lay structural ply then use schluter matting over the top (orange one with grooves)

Does this prep sound reasonable to you and what would you recommend improving?

Also as read on plastering forum never seal with PVA only a tilling primer .

Look forward to you responses & advice.

Thanks