J

Julian 'Farmer' Bonsall

The disc is perpendicular to the tile (being the workpiece. Tile is held as shown in the images - glaze forms 90 degrees to the disc. If one uses any form of chop/sliding saw you typically set the blade at 90 degrees to your work piece ie perpendicular. I usually hold the blade stationary and move the work piece along it.

" Disc perpendicular to the tile surface, disc touching biscuit and ultimately glaze - outer radius/rim of the disc slightly protruding the glaze "

I will take some images as it will be safer than a video.

I suggested that the axis of the blade could be rotated to allow the front or rear to touch - I hold it so all axis are kept perpendicular to the tile so I grind it flat (seemed logical to me rightly or wrongly).

The way I have used the side of a cutting blade such that it is flat across the face of the tile was purposeful rather than using it at an angle which is a little how I feel the convex blade is behaving. As you can see from my images it works but it's different to what I was used to. How do you keep the cut face of the tile flat with the curved disc?

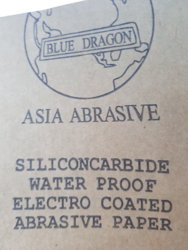

Moving to the silicon paper / flex backing pads - are these used at an angle to the face of the tile also?

I appreciate your help 3_fall and hope I haven't caused more greyness I am sure it's frustrating reading.

I have been tidying the edge of tiles up as I describe for a lot of years and maybe I have been doing it wrong and now a little confused.

" Disc perpendicular to the tile surface, disc touching biscuit and ultimately glaze - outer radius/rim of the disc slightly protruding the glaze "

I will take some images as it will be safer than a video.

I suggested that the axis of the blade could be rotated to allow the front or rear to touch - I hold it so all axis are kept perpendicular to the tile so I grind it flat (seemed logical to me rightly or wrongly).

The way I have used the side of a cutting blade such that it is flat across the face of the tile was purposeful rather than using it at an angle which is a little how I feel the convex blade is behaving. As you can see from my images it works but it's different to what I was used to. How do you keep the cut face of the tile flat with the curved disc?

Moving to the silicon paper / flex backing pads - are these used at an angle to the face of the tile also?

I appreciate your help 3_fall and hope I haven't caused more greyness I am sure it's frustrating reading.

I have been tidying the edge of tiles up as I describe for a lot of years and maybe I have been doing it wrong and now a little confused.

Last edited by a moderator: